PEEK is gaining attention in dental applications — and for good reason. It’s strong, lightweight, biocompatible, and ideal for frameworks, implant structures, and long-term temporary restorations.

But there’s a common frustration: no matter how carefully you set up your job, the result comes out with fuzzy edges, surface burrs, or an uneven finish. You polish, trim, and touch up by hand — only to wonder why your high-end milling machine can’t get it right.

If this sounds familiar, you're not alone. Many labs and clinics encounter these issues not because PEEK is difficult, but because their setup isn’t actually optimized for this unique material.

Here’s why PEEK burrs happen — and how to fix them by understanding the material, the strategy, and most importantly, the machine.

PEEK Isn’t Zirconia — And Shouldn’t Be Treated Like It

Too often, labs try to run PEEK on the same spindle speeds, paths, and strategies they use for zirconia or PMMA. That’s a recipe for subpar results.

PEEK is a high-performance polymer with a low melting point (around 343°C) and a soft, elastic cutting response. If the tool generates too much friction, even slightly, the surface begins to melt or smear — creating micro-burrs and stringy edges.

What’s more, PEEK doesn't “chip” like ceramics. It shears. That means the cutter must slice cleanly, not grind. Any rounding of the cutting edge, overused tools, or poor flute geometry will leave behind unwanted residue.

So before you blame the software or the toolpath, ask yourself: are you using a strategy designed for polymers — or just a generic preset?

Spindle Speed and Feed Rate Matter More Than You Think

To process PEEK cleanly, your spindle must run fast enough to cut — but not so fast that it melts.

Most PEEK jobs perform best in a spindle speed range of 15,000 to 40,000 RPM, depending on tool diameter and number of flutes. A single-flute tool is often preferred for its ability to create larger, cleaner chips and evacuate material without generating too much heat.

However, RPM alone isn’t enough. Feed rate and chip load must be matched carefully. If feed is too slow, the tool rubs rather than cuts. Too fast, and the tool deflects — reducing accuracy and leaving burrs on thin edges or margins.

Some dental milling machines allow you to fine-tune these parameters. But if your system is locked into presets optimized for zirconia, PEEK performance will suffer.

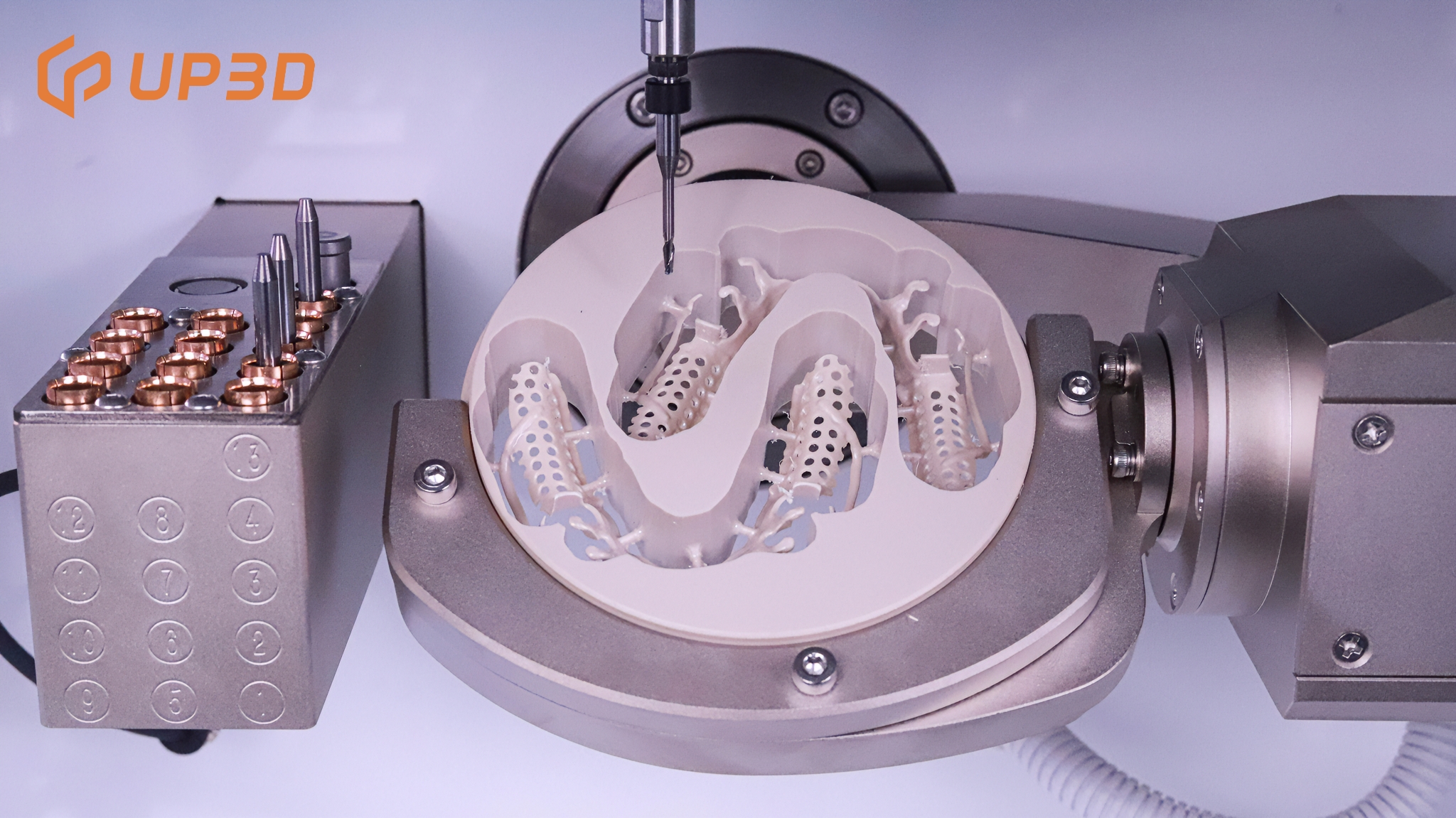

UP3D’s P55D and P53 models are equipped with high-speed spindles that support polymer-optimized milling strategies, and allow for precise adjustment of feed and speed — ideal for PEEK restorations.

Cooling Strategy: Yes, Even in Dry Milling

You may assume that dry milling is always best for polymers. That’s true in many cases — but only if your mill is equipped with the right airflow design.

The biggest problem in PEEK milling isn’t heat alone — it’s static buildup. The chips stick to the surface, gather around the tool, and cling to the restoration. This not only causes burr formation, but also clogs the tool and dulls the cutting edge faster.

That’s why UP3D includes ionizer technology in both the P53DC and P55D systems. Ionized air neutralizes static, improves chip removal, and ensures that milled PEEK parts come out clean — with minimal post-polishing.

Without ionized air or at least a well-directed compressed air flow, even the best milling strategy can be undone by poor chip evacuation.

Is Your Milling Machine Designed for PEEK?

Not all dental mills are built with polymers in mind.

Some systems, especially those designed primarily for zirconia, may lack:

High enough spindle speed for smooth polymer cutting

Adjustable CAM strategies for soft materials

Airflow systems optimized for chip evacuation

Tool holders compatible with polymer-specific burs

And if your machine requires an external compressor to manage chip clearing, that’s an added complexity — and a potential source of inconsistent airflow.

UP3D’s P55D was engineered specifically to eliminate these bottlenecks. It’s a compressor-free system with a clean internal airflow path, support for a full range of materials (including PEEK and PMMA), and a CAM engine capable of adapting to soft-material strategies.

If you regularly work with PEEK or plan to expand into polymer-based frameworks, investing in a machine designed to handle these challenges upfront will save you hours of finishing work down the line.

Burr-Free PEEK Starts With the Right Tools

PEEK isn’t inherently difficult. But milling it well requires attention to detail — in your spindle speed, tool choice, chip evacuation, and machine configuration.

If your current system produces more burrs than benefits, it might be time to ask: Was this machine really built for polymers?

And if the answer is no — now you know what to look for in one that is.

Ready to mill cleaner, faster PEEK restorations? Talk to our team about how the UP3D dental mills can upgrade your workflow.