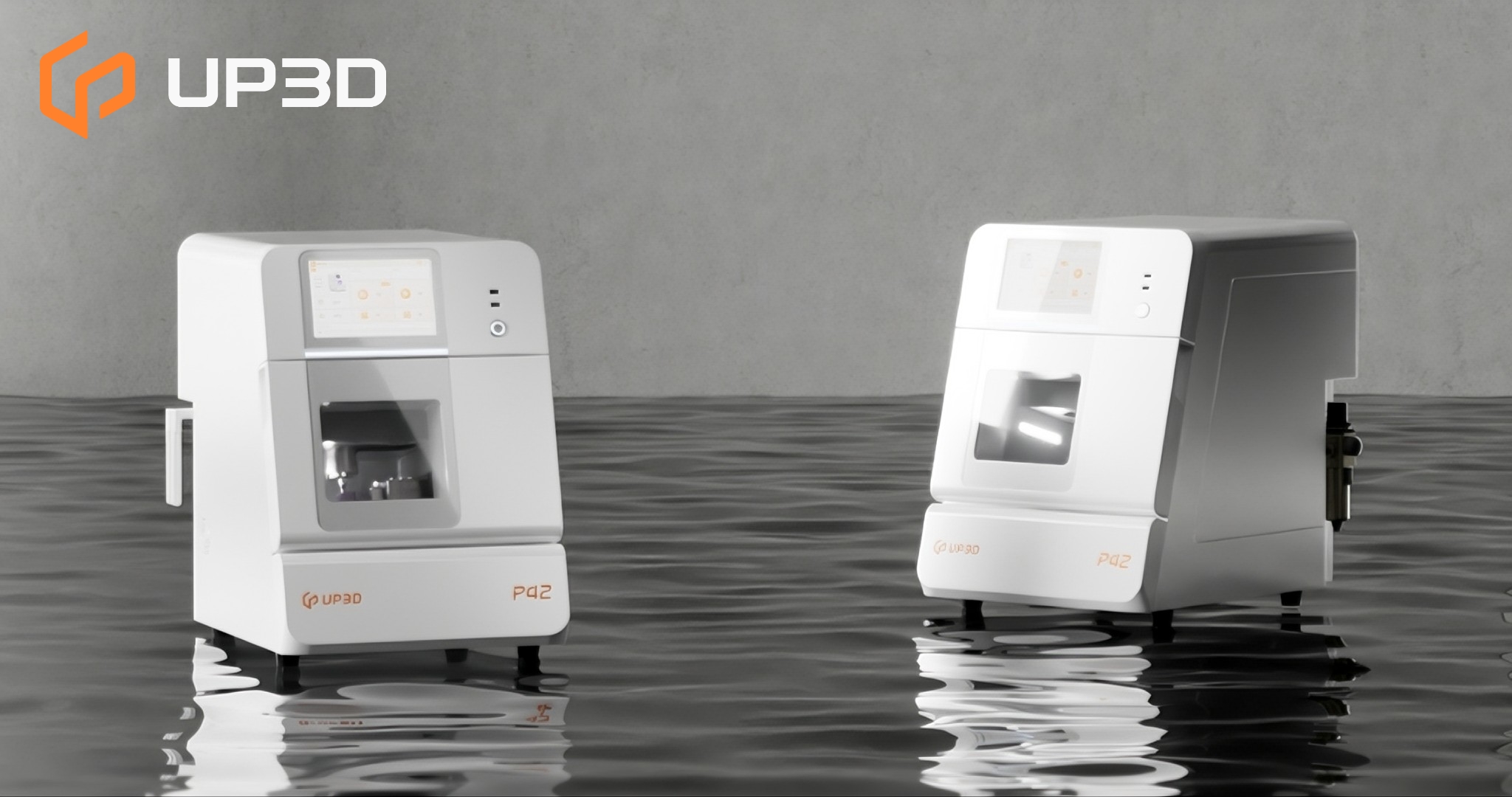

Wet milling is an essential technique in dental restoration, especially when handling intricate cases. With the introduction of UP3D’s P42, wet milling reaches new levels of efficiency and environmental responsibility. This advanced machine not only simplifies the milling process but also integrates seamlessly with digital workflows, offering a comprehensive solution for dental labs, clinics, and in-house labs.

Pure Water Milling: Simplifying the Process

What sets the P42 apart is its pure water milling technology. By using purified water instead of chemical additives, the P42 reduces costs and eliminates the need for complex waste management. This is a significant step forward for dental practices and labs looking for a more eco-friendly, efficient milling process. The use of pure water makes the entire workflow cleaner, easier to manage, and less costly over time, all while ensuring optimal material preservation.

Tackling Undercuts: Precision Without the Hassle

Dealing with undercuts in restorations often requires tedious manual adjustments. The P42 addresses this challenge with its undercut removal capability, using an A-axis tilt of ±20° and UPCAM software. This allows for precise milling, eliminating the need for manual refinements, which saves time and improves the overall accuracy of the fit. For labs and clinics working on complex restorations, this means less rework and quicker turnaround times.

Seamless Integration for Immediate Restorations

Efficiency doesn’t stop at milling. The P42 integrates effortlessly with SOREAL immediate restoration system, enabling a smooth transition from scanning and design to milling. This all-in-one approach streamlines the restoration process, minimizing the chances for error and maximizing productivity. Dental teams can focus on providing patient care while the P42 handles the technical work with accuracy and reliability.

Remote Monitoring: Flexibility and Control

Thanks to its integration with Millmind software, the P42 can be controlled remotely, offering real-time monitoring of the milling process. From tool life tracking to production status updates, users can manage their workflow from anywhere. This feature is especially beneficial for labs and clinics juggling multiple projects at once, giving them the flexibility to oversee operations without being physically present.

A New Standard for Complex Restorations

The P42 is designed to take the complexity out of dental restorations, offering advanced milling technology that reduces manual effort and enhances workflow efficiency. With its eco-friendly pure water milling, precise undercut removal, and remote monitoring capabilities, the P42 sets a new standard for dental labs, clinics, and in-house labs looking to streamline their operations. Experience the future of wet milling with the P42 and take your dental restoration processes to the next level.

Explore more about the P42 dental milling machine and how it can benefit your practice by visiting UP3D’s Product Page.