Investing in a dental milling machine is a significant decision for any dental lab or clinic. The right choice can improve efficiency, precision, and profitability, while the wrong one may lead to high maintenance costs and workflow inefficiencies.

But how do you know which milling machine best fits your needs? The market is full of options—4-axis vs. 5-axis, wet vs. dry, manual vs. automated—and understanding the differences is essential to making an informed decision.

Here’s a practical breakdown of the key factors to consider before making your purchase.

Wet vs. Dry Milling: Which One is Best for You?

One of the first decisions to make is whether you need wet milling, dry milling, or both.

Wet milling is commonly used for glass ceramics, titanium, and composite resins. It provides a smoother surface finish and helps prevent microfractures in the material. Many dental clinics and labs use wet milling for same-day restorations where aesthetics and surface integrity are critical.

Dry milling is ideal for zirconia, PMMA, PEEK, and CoCr. It’s generally faster, easier to maintain, and does not require additional cooling liquids. Dry milling is the go-to choice for high-production dental labs handling a large volume of restorations daily.

💡 Tip: If your lab or clinic frequently works with glass ceramics or titanium, consider a machine like the UP3D P42, which supports pure water milling to maintain material purity. If you primarily handle zirconia, PMMA, or CoCr, a 5-axis dry milling machine like the P53, P53DC, or P55D offers a more efficient workflow.

4-Axis vs. 5-Axis Milling: Understanding the Differences

Milling machines typically come in 4-axis and 5-axis configurations, and the right choice depends on the complexity of restorations you handle.

4-axis milling covers most standard dental applications, including crowns, inlays, and veneers. It provides excellent precision but has limitations in handling deep undercuts or restorations requiring multiple angles.

5-axis milling offers greater flexibility, allowing for full control over milling angles. This is especially useful for implant-supported restorations, full-arch prosthetics, and advanced aesthetic restorations.

💡 Tip: If your practice focuses on basic restorations, a 4-axis machine like the UP3D P42 can provide high efficiency at a lower cost. If you need more advanced milling capabilities, a 5-axis system like P53, P53DC, or P55D ensures greater precision and versatility.

Automation: Do You Need Unattended Milling?

Automation is a key consideration, especially for high-production dental labs that require 24/7 milling with minimal manual intervention.

Manual milling machines require technicians to load materials and monitor the process. This is ideal for clinics or small labs where production volume is lower.

Automated milling machines can automatically switch materials and tools, reducing downtime and increasing production capacity.

💡 Tip: For large labs looking to scale production, the UP3D P53DC features a 12-disc automatic changer, allowing continuous, unattended milling of multiple materials. If you're looking for a plug-and-play solution, the P55D eliminates the need for compressed air, simplifying installation and maintenance.

Cost vs. Productivity: Making the Right Investment

Cost is always a factor, but instead of focusing on price alone, consider long-term productivity, maintenance, and return on investment.

For small clinics or labs: An affordable, compact milling machine that supports same-day restorations is often the best choice.

For growing dental labs: Look for a milling machine that balances affordability with scalability—something that can handle increasing workloads without requiring immediate upgrades.

For high-volume production labs: Investing in a high-capacity, automated milling machine can drastically cut labor costs and maximize output.

💡 Tip:

P42 is a cost-effective choice for clinics needing same-day restorations with glass ceramics or composite materials.

P53 offers a balance between affordability and advanced capabilities, making it ideal for mid-sized labs.

P53DC is a high-efficiency solution for large labs that need automated disc changing for non-stop production.

P55D is the perfect option for clinics or labs that need a high-performance milling system without the complexity of compressed air setup.

Choosing the Right Milling Machine for Your Needs

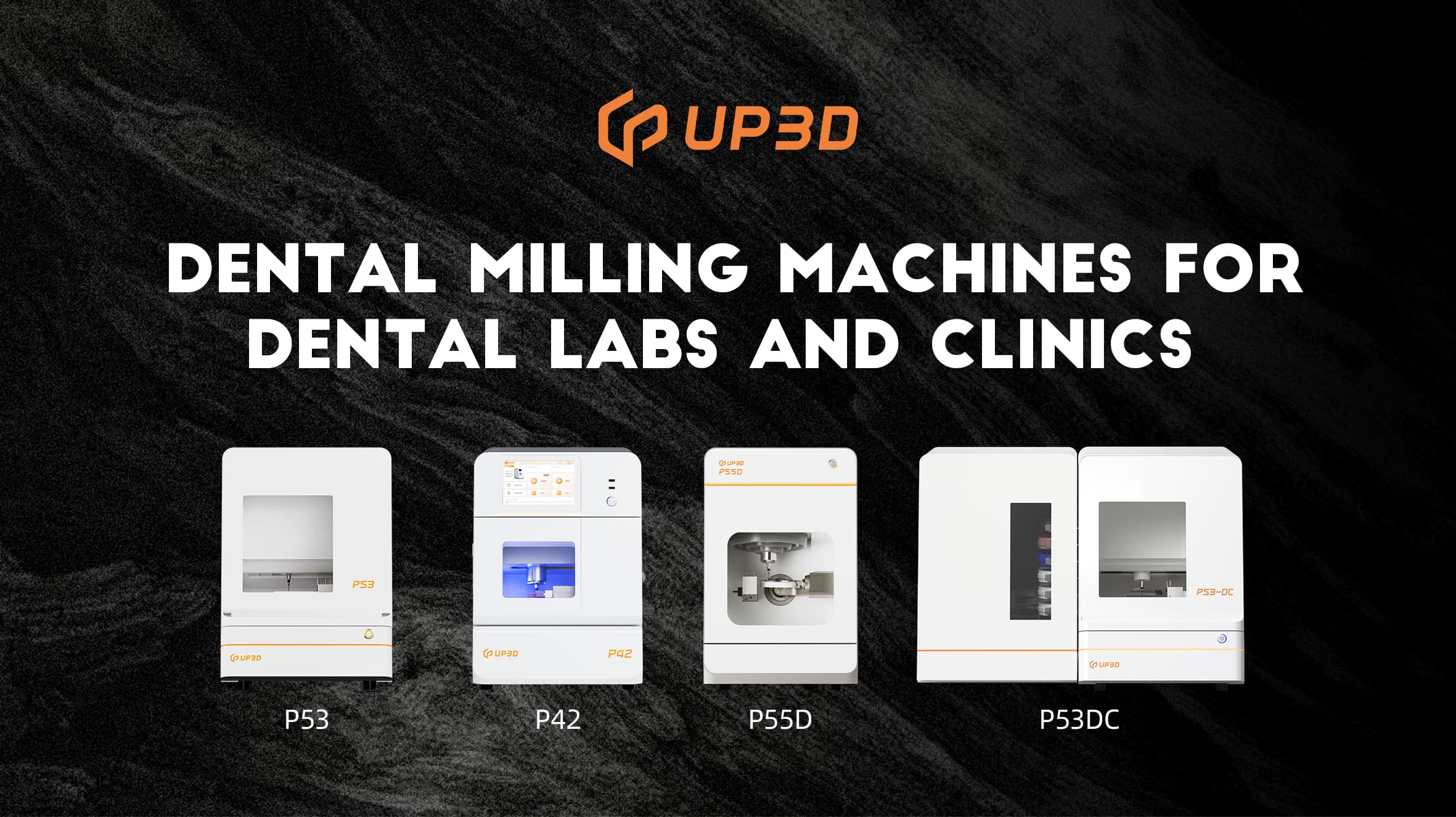

Finding the right dental milling machine is about understanding your workflow, production goals, and material requirements. Whether you're looking for a cost-effective wet milling solution for your clinic or a high-volume automated system for your lab, UP3D offers a range of options tailored to your needs.

Still unsure which milling machine is best for your practice? Explore UP3D’s milling machines, contact our experts for a free consultation.